our machines building your dreams

Brass Fabrication Services

Brass is the metal you reach for when strength, conductivity, and corrosion resistance can’t be compromised. It’s trusted across demanding industries, from electrical and HVAC to industrial machinery, because it performs under pressure and machines cleanly. At ABT Metals, we know what it takes to turn raw brass into production-ready parts built for real-world demands. You can rely on our brass fabrication services.

Why Brass Works for Complex Manufacturing

Brass stands out for manufacturers who need parts that perform under pressure without sacrificing precision, appearance, or long-term reliability. It’s a material that checks a lot of boxes, especially in industries where quality and consistency matter.

Easy to Machine, Built to Last

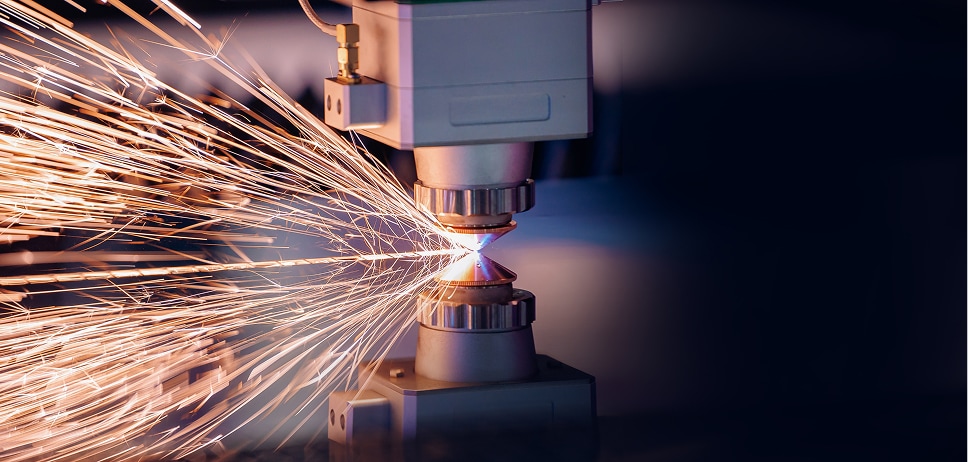

One of brass’s biggest advantages is how well it machines. It cuts cleanly, holds tight tolerances, and makes high-repeat production smoother and more efficient. That’s why it’s a top choice for detailed components like inserts and bushings, or anywhere precision matters.

Brass also resists corrosion naturally, which means it holds up in harsh environments without coatings or extra treatments. That’s a big plus for applications in HVAC, industrial equipment, and plumbing, where moisture and exposure are part of the job.

Good Looks, Without the Trade-Offs

Beyond performance, brass brings a distinctive, professional look. Its gold-like finish makes it popular for visible components like architectural fittings and fixtures. Despite its good looks, brass still brings the same strength and durability you’d expect from a workhorse metal.

Conductivity Where It Counts

Brass is highly conductive, making it a smart option for electrical components like terminals and switch parts. It handles current well, doesn’t degrade easily, and supports efficient power flow, which are key benefits in industries like electronics, HVAC, and energy.

Whether it’s stamped, machined, or formed, brass delivers the versatility and performance that complex manufacturing demands. Industry leaders trust brass across applications because it works in the real world.

Precision Brass Fabrication Services, All Under One Roof

At ABT Metals, we don’t just work with brass; we know how to get the most out of it. Our in-house operations handle everything from early-stage prototyping to full-scale production, all with the speed and accuracy you need to stay competitive.

Whether you’re looking for one-off custom parts or thousands of components on a tight deadline, we have the tools and experience to keep your project moving.

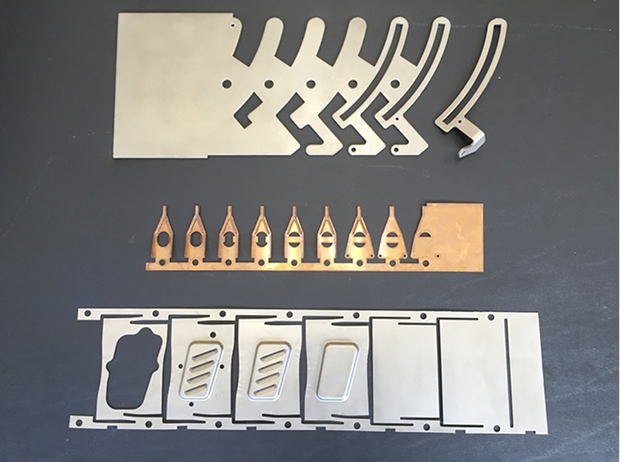

Our brass fabrication services include:

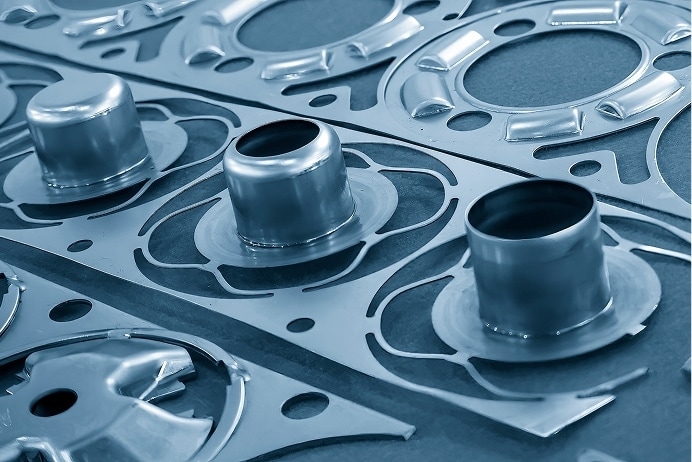

- Brass stamping services – Clean, uniform parts produced with tight tooling tolerances for brackets, housings, terminals, and more.

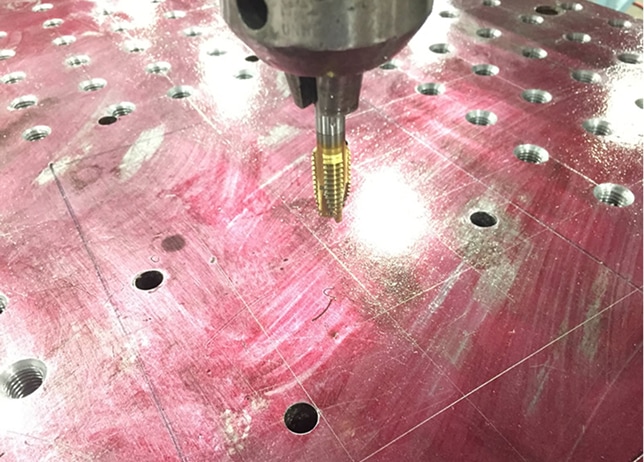

- Brass CNC machined parts – Precision-milled and turned components with repeatable accuracy, ready for critical assemblies.

- Forming and bending – In-house press brake and custom tooling support complex shapes without compromising strength.

- Short-run production – Ideal for prototyping or pilot builds when quality matters more than quantity.

- High-volume manufacturing – Scalable production lines capable of handling consistent part runs for large-scale demand.

- Secondary operations and assembly – Deburring, drilling, tapping, and light assembly to deliver fully finished parts that are production-ready.

We manufacture all of this right here in North Carolina at our 150,000-sq.-ft. facility. built for speed, our shop delivers high-performance parts on time and to spec, no matter how complex your brass component must be.

Why Choose ABT for Brass Fabrication Services?

When you need brass parts that look sharp and fit right, ABT Metals is the partner that delivers. Our team works with high-quality brass alloys every day, shaping them into components that meet the tightest tolerances and toughest performance standards.We serve OEMs, engineers, and purchasing teams who are solving complex problems. That means every part we produce, whether it’s a small-batch prototype or a full-volume run, offers consistency and accuracy for real-world performance.

What we offer:

- Engineering support and prototyping to fine-tune designs before production

- Full traceability and process control

- A facility designed for throughput and flexibility: high-run capacity with the responsiveness of a custom shop

From material selection to final inspection, we take pride in helping our customers get the most out of their brass. And with all fabrication, machining, and stamping done in-house, we move faster and control quality from start to finish.If your project calls for brass stamping services with no room for error, we’re ready to help you make it happen.

Let’s Get to Work on Your Brass Fabrication Project

ABT Metals offers the brass fabrication services you need to stay on schedule and on spec. We’ve spent decades helping manufacturers across North Carolina and beyond turn complex requirements into high-performance components quickly and accurately.

Whether you need brass stamping services, brass CNC machined parts, or other fabrication services, our team is here to make it happen with complete end-to-end production support. Request a quote or contact us today to talk through your project.

Additional Services We Offer

At ABT Metals Manufacturing, we take pride in offering the highest quality metal fabrication services in North Carolina.

Give us a call or fill out the form and our team will be in touch as soon as possible.

*marks a required field

Quick Contact

"*" indicates required fields