our machines building your dreams

Alloy Steel Fabrication Services

ABT Metals provides alloy steel fabrication services for OEMs and manufacturers with demanding performance, strength, and precision requirements. We operate from a 150,000 sq. ft. facility and deliver consistent quality for every part — from initial design to full-scale production. Our team fabricates and machines complex components across a wide range of alloy steel grades, supporting industries like aerospace, automotive, energy, and heavy equipment.

Our reputation for quality work, engineering support, and production flexibility makes us a reliable partner for high-spec alloy steel fabricated parts.

Alloy Steel Grades & Their Applications

ABT Metals processes a variety of alloy steels selected for their strength, durability, and performance in extreme environments. Our team can fabricate parts from customer-specified grades or recommend suitable materials based on design and performance needs.

We commonly work with:

- 4140 Alloy Steel – A chromium-molybdenum grade known for toughness, high fatigue strength, and abrasion resistance. Often used in gears, crankshafts, and downhole tools.

- 4340 Alloy Steel – Offers deeper hardenability and higher tensile strength than 4140. Suited for aerospace and defense components subjected to extreme stress.

- 8620 Alloy Steel – A low-carbon alloy ideal for case-hardening. Popular in automotive drivetrain parts like camshafts, gears, and bushings.

- 4130 Alloy Steel – A versatile, weldable grade valued for its strength-to-weight ratio. Frequently used in aerospace, motorsports, and high-strength tubing.

Each alloy offers specific benefits based on heat treatment compatibility, corrosion resistance, formability, and hardness. We tailor our approach to match material properties with your performance and application goals.

Advanced Fabrication Techniques for Alloy Steel

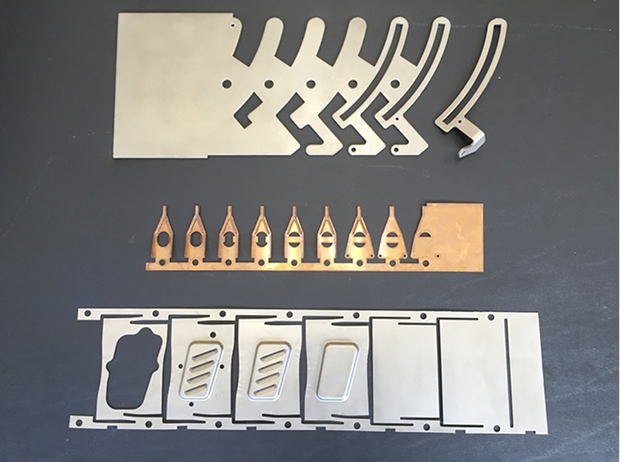

At ABT Metals, we combine deep material knowledge with precision manufacturing techniques to produce alloy steel fabricated parts that meet rigorous industry standards. Our team uses a wide range of in-house capabilities to support part geometries ranging from simple brackets to complex formed assemblies:

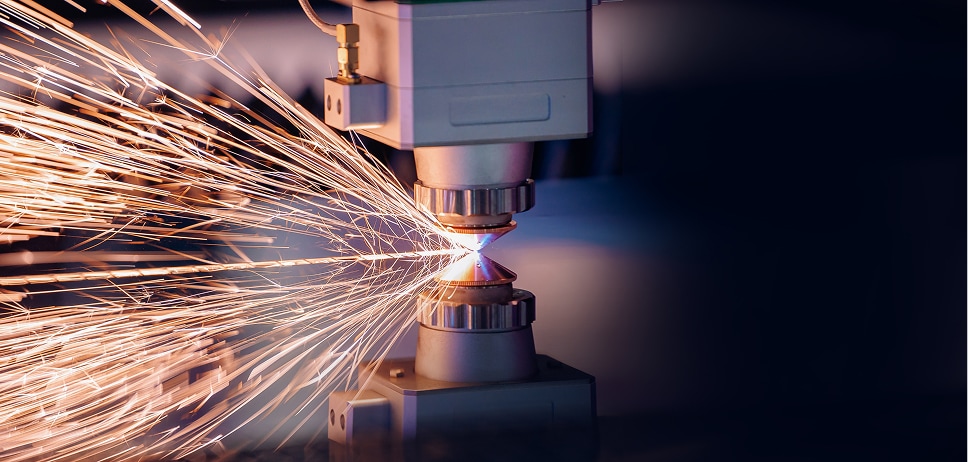

- Laser Cutting – Delivers tight-tolerance flat patterns with clean edges and minimal heat-affected zones, ideal for precise base components.

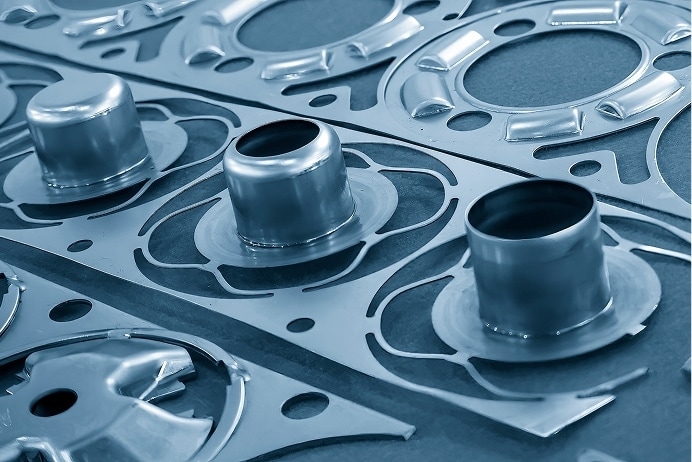

- Deep Drawing & Metal Stamping – Used for high-volume parts with consistent geometries. Suitable for forming cups, enclosures, and high-strength housings.

- Tube Bending – Supports structural alloy steel tubing for aerospace frames, energy infrastructure, and medical carts.

- Welding – MIG, TIG, and robotic welding services for clean, durable joints across various thicknesses and geometries.

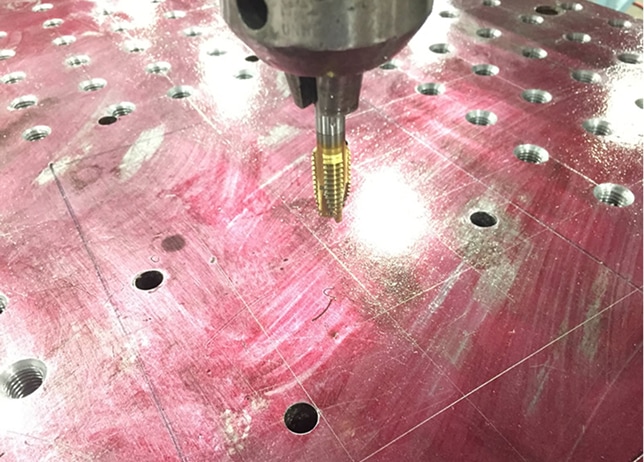

- Alloy Steel CNC Machining – Multi-axis CNC milling and turning with tight tolerances and smooth surface finishes for critical parts.

- Finishing & Deburring – Removes burrs, smooths edges, and prepares components for coating or assembly.

By controlling every step in-house, including tooling, fixturing, and inspections, we help customers reduce lead times and ensure quality from the first piece to the last.

Industries We Serve with Alloy Steel Fabricated Parts

ABT Metals supports a wide range of industries that require high-performance fabricated alloy steel components. Our parts are engineered and produced to meet strict tolerances, traceability requirements, and long-term durability goals.

Industries we serve include:

- Aerospace – Lightweight, fatigue-resistant components for airframes and support structures

- Automotive and Aftermarket – Brackets, suspension components, and custom driveline parts

- Energy and Utilities – Durable, corrosion-resistant parts for power generation and oil & gas

- Construction Equipment – Heavy-duty parts capable of withstanding rugged environments

- Medical and Lab Equipment – Precision-formed components for diagnostic and surgical systems

- Industrial Machinery – Shafts, bushings, and housings for high-volume manufacturing systems

Our alloy steel fabrication expertise helps customers across these industries improve component performance, reduce weight where necessary, and increase service life.

Why Partner with ABT Metals for Alloy Steel Fabrication?

As a full-service job shop, ABT Metals offers a complete solution for alloy steel fabrication services — from engineering support to final inspection. Our team is equipped to handle complex parts, evolving specs, and high-volume production with accuracy and repeatability.

We bring the following advantages:

- State-of-the-art CNC and fabrication equipment for repeatable precision

- Engineering expertise for manufacturability reviews and prototype development

- Rigorous quality control, including in-house inspections and testing

- Decades of proven experience working with alloy steel for OEM applications

Our customers count on us for durable parts, dependable delivery, and transparent communication every step of the way.

Trust ABT Metals for Your Alloy Steel Fabrication Service Needs

Looking for a fabrication partner that understands the demands of alloy steel? Contact ABT Metals to request a quote or discuss your project requirements with our team.

Additional Services We Offer

At ABT Metals Manufacturing, we take pride in offering the highest quality metal fabrication services in North Carolina.

Give us a call or fill out the form and our team will be in touch as soon as possible.

*marks a required field

Quick Contact

"*" indicates required fields